TIME: 2021-11-11

On November 30th, the annual conference of China Welding Steel Pipe Academic Conference was grandly held in Jinan. About 80 domestic and foreign welded steel pipe enterprises participated in the conference. Inspired by the strong momentum of the 19th National Congress, the conference discussed the development trends of the welded steel pipe industry. The 19th National Congress undoubtedly ushered in a new stage of China's political and economic development, which not only attracted domestic attention but also international attention. When China became the world's second largest economy, its political and economic changes also affected the global market. With the definition of major contradictions in Chinese society, it means that future economic issues will be at the core of high-level attention.

After the 19th National Congress, the government will implement the following measures: 1. Promote high-quality economic development; 2. Strive to overcome the three major barriers of development mode, economic structure, and growth momentum; Accelerate the construction of a modern economic system, emphasizing quality first and efficiency first. The representative meeting coincides with the recovery of the domestic and foreign steel pipe industry, and the enthusiasm and expectations for attending the meeting are self-evident.

Two keynote speeches were given at the meeting, and Professor Wang Xiaoxiang, former director of China Petroleum Bohai Equipment Steel Pipe Design and Research Institute, gave a review and outlook on the operation and technological progress of China's welded pipe industry since 2016.

The main viewpoint is that after years of rapid development, China's welded pipe industry has gradually slowed down as the national economy enters a new normal. The contradiction between overcapacity and reduced demand has become increasingly prominent. Since the second half of 2013, due to the delayed start of key oil and gas pipeline projects, the usage of pipeline steel pipes has significantly decreased, enterprise orders have been seriously insufficient, economic benefits have declined, and the growth rate of welded pipe production has significantly declined. The export rate of welded pipes has reached a new low, and prices have declined. Welded pipe enterprises have encountered great difficulties. Under the new normal, Chinese welded pipe enterprises are actively transforming their development models, focusing on implementing process improvement and technological innovation, promoting grade upgrading and product structure adjustment, comprehensively improving the performance and physical quality of steel pipe products, and achieving great results in scientific and technological progress.

There is still significant development space for China's oil and gas pipelines, and the national "Thirteenth Five Year Plan for Natural Gas Development" has put forward new grand goals. In 2017, the construction of the China Russia crude oil pipeline, the Shaanxi Beijing natural gas fourth line, and the China Russia natural gas pipeline east line began successively, and the construction of oil and gas long-distance pipelines gradually recovered, and the welded pipe market will gradually improve. I believe that China's welded pipe industry can usher in new development after structural adjustment, independent innovation, and market expansion.

Sun Yongxi, Chairman of the Expert Committee of the Shanghai Steel Pipe Industry Association, delivered a discussion on the transformation and upgrading of small and medium-sized steel pipe enterprises in China after the 19th National Congress.

The main viewpoint is that in the future, the competition in the steel pipe industry will no longer be price competition, but efficiency and quality competition. In today's steel pipe industry with excess manufacturing capacity, it is inevitable for enterprises to make small profits or losses. In this situation, how to get out of the predicament, what mode to rely on to achieve adjustment, and what is the future of the industry? It is something that we all care about. After industry surplus, relying on technological progress and management innovation, adjusting product structure, improving product quality, and taking the path of high-quality development have become inevitable. The main lever for achieving adjustment is innovation, which requires innovative business models, quality and cost management models, and new product development paths for innovative enterprises.

Technological innovation is the foundation of industrial upgrading, and upgrading strategies include establishing product concepts, selecting suitable markets, and formulating correct product upgrading plans. Take the path of differentiation, high added value, and high-quality steel pipes. The leading ideology is to manufacture high-quality steel pipes and build an honest brand. Transformation and upgrading do not necessarily require expanding scale and exploring new fields. But it is based on market changes, constantly adjusting product structure and improving product quality, which is itself the result of transformation and upgrading. Making our products more precise and superior is also the best embodiment of transformation and upgrading.

At the meeting, 14 professional papers on welded steel pipes were published, and after strict evaluation by the expert team, 2 papers were awarded first prize. Xie Shiqiang, member of the Shanghai Steel Pipe Expert Committee and chief expert of Baosteel Bar and Steel Business Unit, titled "Research and Application of UOE Welded Pipes for Acidic Environments"; Engineer Xu Gang from Bohai Equipment Steel Pipe Design and Research Institute, "Grinding Robot for End Welds of Submerged Arc Welding Pipes.". Three papers were awarded the second prize, and Zhao Bo, an engineer from Bohai Equipment Steel Pipe Design and Research Institute, conducted experimental research on submerged arc welding technology with extended multi wire welding wire; Professor Xiao Furen from Yanshan University's "Overall Quality Evaluation of API5L HF-ERW Steel Pipe" and engineer Liu Haizhang from Baoji Petroleum Steel Pipe Co., Ltd.'s "2205/X65 Bimetallic Metallurgical Composite Pipe and Welding Process for Oil and Gas Gathering and Transportation".

Development trends

There are three topics worth our attention in the professional research papers presented at this conference, which also reflect the development trend of China's welded steel pipe industry's transformation and upgrading in 2017:

Baosteel's research on pipeline steel technology has taken the lead in the world's peers

1. With the improvement of steel grade and hardness, the difficulty of pipeline steel's resistance to HIC and SSCC is increasing. X65MS remains the mainstream steel grade for pipeline steel pipes used in acidic environments in the international market. In practical engineering, X65MS and above steel grades tend to use round bar samples for tensile testing. X70MS and X80MS steel grades also have a small number of engineering applications. It is recommended to conduct high HIC resistance or SSCC performance tests according to the actual service environment.

2. The pure purification and stable rolling of steel have created conditions for the economical application of rolled flat steel plates and some steel plates in acidic environments for pipeline steel pipes.

3. Since its production in 2008, Baosteel UOE has conducted research and development on a series of pipeline pipes for acidic environments. Through the purification and rational composition design of low C, low Mn, ultra-low P, and S, non-metallic inclusions and center segregation control are controlled. The TMCP rolling process is used to produce raw steel plates for pipe production (including rolled and flat plates). By controlling the maximum compression rate of 0.25% and the expansion rate of 0.8% -1.2%, the residual stress in pipe production is reduced and homogenized to achieve high dimensional accuracy. The mechanical properties and HIC and SSCC resistance of X65 and below straight seam submerged arc welded pipes are excellent, and they have been commercially supplied in bulk. The UOE of X70MS meets the service conditions. The welded pipe has also been successfully developed.

Robots have begun to be applied in welded steel pipe enterprises in China

The pipe end weld grinding machine is a process technology equipment used for grinding the inner and outer welds of straight and spiral submerged arc welded pipes. The current grinding of internal and external welds is completed by manually controlling the internal weld grinding machine and the external weld grinding machine, which occupies more workstations, requires more operators, takes a long time for material transportation, and is not easy to ensure the quality of weld grinding. In order to solve the above shortcomings of existing grinding machines, modern detection, control, and network communication technologies are applied to develop a robot for grinding the inner and outer welds of submerged arc welded pipe ends, achieving fully automatic grinding of the inner and outer welds.

This is an innovation. The intelligence of production equipment, automation of workshops, networking of enterprise management, and socialization of production factors are collectively referred to as Industry 4.0. The emergence of Industry 4.0 is a way for industry to explore its own development. The highly intelligent processing equipment is the development direction of the future steel pipe manufacturing industry.

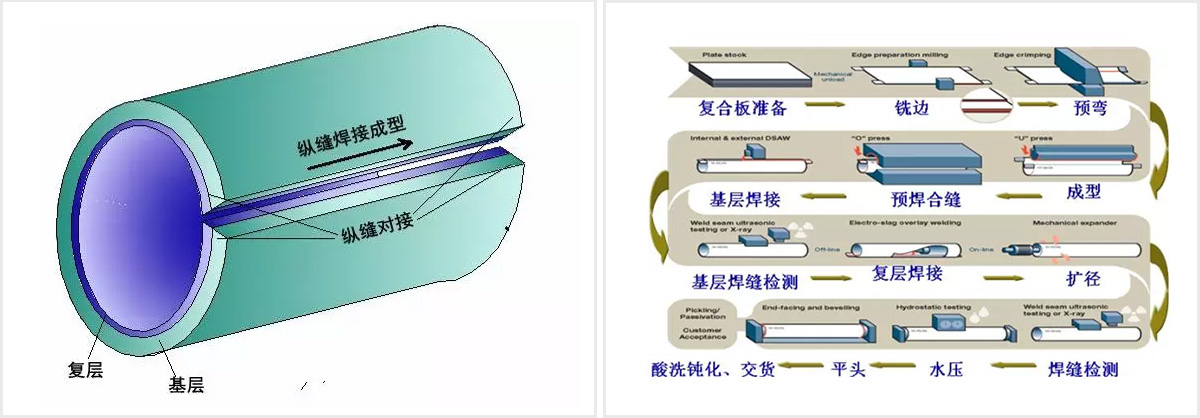

There are three papers focusing on the research of bimetallic composite steel pipes, which are worthy of attention

"Research and Development of Composite Pipeline Steel Products" by Dr. Liang Xiaojun from Baosteel Central Research Institute, "Research on Welding Technology of Bimetallic Nickel Based 825 Composite Pipe" by Engineer Wei Tao from Harbin Welding Research Institute, and "Research on 2205/X65 Bimetallic Metallurgical Composite Pipe and Welding Process for Oil and Gas Gathering and Transportation" by Engineer Liu Haizhang from Baoji Petroleum Steel Pipe Co., Ltd. (National Petroleum and Natural Gas Pipeline Engineering Technology Research Center).

Application of 2205 stainless steel lining:

Petrochemical industry: mainly used in acidic oil and gas gathering pipelines, offshore pipelines, and chemical heat exchangers containing Cl -/CO2 and H2S corrosive media.

Seawater treatment: Due to the formation of microbial films on the metal surface of seawater, the corrosion potential increases, causing pitting and crevice corrosion, which is used in the manufacturing of seawater exchangers.

Paper industry: Due to its excellent wear resistance, stress corrosion, and fatigue corrosion performance, it is used in paper pressure drums, pulp digesters, etc.

Fertilizer industry: chloride ion water heat exchange equipment.

The welding of composite pipes belongs to the welding of dissimilar metal materials, which requires layered welding, that is, multi-layer and multi pass welding is used for the welding of the cladding, transition layer, and base layer. It is necessary to consider the development of welding processes from the aspects of welding groove design, welding method selection, welding material selection, welding sequence, etc., to ensure the good mechanical properties of the welded joint and the corrosion resistance of the cladding weld.

(The above article is reprinted by the Shanghai Steel Pipe Industry Association)

High-end pipe manufacturing equipment

manufacturing experience

professional team

Plant a total area of 10,000

square meters

9 inventions, 11 utility models <bR />2 appearance designs

2016-2019 © Huajin Heavy Equipment All Rights Reserved Xiang ICP Preparation 12002607 Number