TIME: 2018-07-12

In recent years, China's oil and gas exploration and development areas in the South China Sea have mainly been concentrated on the northern continental shelf. Within this hundreds of thousands of square kilometers of continental shelf area, over one billion tons of equivalent oil and gas reserves have been discovered, contributing nearly 300 million tons of petroleum products over the past 20 years. Some oil fields have been located at the edge of the continental shelf, such as Panyu 30-1 and Liuhua 11-1, where large oil and gas fields are located on the edge or upper edge of the continental slope; The Liwan 3-1 gas field, the first potential commercial gas field discovered in China's South China Sea slope area in 2006, is located in a deep-water area at a depth of 1500m.

To develop deepwater oil and gas fields, it is necessary to fully understand all the characteristics of the corresponding oil and gas field (underground, seabed, sea, sea surface, transportation methods, etc.) and the economic viability of the entire underground resource development, formulate response strategies and plans, comprehensively solve a series of technical and economic problems related to deepwater and shallow buried oil reservoir engineering, deepwater drilling engineering, deepwater oil and gas gathering and transportation engineering, etc. (especially the problem of natural gas sales market). This article mainly discusses the problems, technical challenges, design ideas, and solutions of oil and gas gathering and transportation systems in the development of deepwater areas on the continental slope from the perspectives of deepwater ocean engineering and the topography and geomorphology of the continental slope. It points out that the development and transportation of deepwater oil and gas fields should be based on the objective needs of several key points such as the location of the oil and gas field, the seabed topography and geomorphology, the characteristics of oil and gas products, transmission paths, storage methods, export forms, supply guarantee, market, and the overall economic feasibility of the plan to comprehensively solve the problems of deepwater and continental slope gathering and transportation.

Reflection and selection of oil and gas gathering and transportation plans in the deep-water continental slope area of the South China Sea

1.1 Main gathering and transportation methods for oil and gas field development in deepwater continental slope areas

The unique geographical location and environment of the South China Sea result in multiple options for oil and gas gathering and transportation. At present, there are five main gathering and transportation schemes for the development of oil and gas fields in deep water and continental slope areas.

1) On site gathering and transportation processing. Gathering and transportation treatment is carried out near the seabed wellhead, such as dehydration, sand removal, and oil collection of common crude oil underwater, and injection of water and sand into specialized injection wells. On land, this is the simplest well site mode; In shallow water, the commonly known wellhead treatment platform can also be used; However, in deep water, the required products for underwater wellhead, underwater separation, underwater pressurization and injection can be called the high-precision "pearls on the crown" of the mechanical manufacturing industry. It is extremely difficult to accurately embed these "pearls" on the preset "crown" on the seabed by underwater robots. For example, if only the water working ship and underwater robot cooperate to complete the basic positioning action, the navigator needs to control the positioning action of the underwater robot at a depth of 1500m through a lowered umbilical cable with a length of 1800-2000m. If there is a slight difference, not only will the action not be completed, but the robot may also be entangled on the lowered equipment or base. Therefore, for deep-water installation operations, even the world's top companies and most skilled navigators are like walking on thin ice, and all connections must withstand a pressure of 35-70MPa. Therefore, "on-site gathering and transportation treatment" in deep water areas is still in the exploratory stage, especially in the field of underwater compression technology.

2) Collect and transport nearby. Transport from the bottom of the water to the surface, and use surface facilities such as TLP, Spar, FPSO, and semi submersible floating devices for collection and transportation treatment. The dry wellhead (similar to shallow water wellhead platform mode+platform wellhead lift compensation) and wet wellhead (similar to underwater wellhead in on-site gathering and transportation, such as Liuhua 11-1 oilfield and Lufeng 22-1 oilfield) enter the floating device through the riser system, and are then processed and exported by the floating device; If it is natural gas, dry or wet gas will be exported to onshore factories through submarine pipelines.

3) Remote gathering and transportation processing. Transporting from the bottom of the water for a distance or passing through multiple points to the surface (within the range where natural energy can ensure safe flow), utilizing surface facilities such as fixed platforms or tension legs far from underwater well areas, column platforms, floating production and storage vessels (such as TLP, Spar, FPSO), and semi submersible floating devices for treatment and export; If it is natural gas, dry or wet gas will be exported to onshore factories through submarine pipelines. This gathering and transportation method is commonly used in deepwater satellite oil fields abroad, and will also be adopted in the upcoming Liuhua 16-2 oilfield in China.

4) Terminal gathering and transportation processing. Transporting gas from the bottom of the water for a certain distance or passing through multiple points to collect and transport it to the nearest location to the consumer market for processing. For example, some offshore gas fields in foreign countries have built gas plants near the consumer market or near the main pipeline network to process deep-sea gas.

5) Mixed gathering and transportation processing. The combination of the above four gathering and transportation treatment methods has led to common gathering and transportation schemes and technical routes, such as "dry wellhead and wet wellhead", "submarine hard pipeline and floating hose line, soft riser and hard riser", "floating pressurization treatment+storage or fixed pressurization treatment+storage", formed by the characteristics of oil and gas products, flow guarantee technology, pressurization transportation, etc.

1.2 Selection of Main Gathering and Transportation Methods for Oil and Gas Field Development in the Deep Water Slope Area of the South China Sea

For the Liwan 3-1 deep-water gas field project in the northern slope area of the South China Sea, a "deep shallow land" development model has been proposed for the first time, which is a gathering and transportation development model of "underwater wellhead+underwater east and west gathering areas and finally gathering+double pipe climbing to the central processing platform of the slope edge+long-distance pre buried mixed transmission pipeline+land natural gas processing plant before entering the Guangdong pipeline network". The main basis for adopting this mode is as follows:

1) From the perspective of the sea conditions in which the gas field is located, the South China Sea is characterized by frequent typhoons and unique internal wave currents, making it one of the worst environmental conditions in the world. All facilities exposed to the sea must have the ability to withstand the aforementioned harsh environments (extreme wind and wave heights) and ensure stable production for 20 years. The platform chosen for this project is the most secure fixed platform, which has the dual advantages of safety and economy, as well as nearly 20 years of successful operation experience in China; The key challenge lies in whether the long-distance mixed transportation flow guarantee technology can ensure that underground oil and gas can reach a suitable location for constructing a fixed platform on the continental slope from the oil and gas field location on the slope. The oil and gas transportation in this project faces two major challenges: firstly, relying on natural energy reaching the wellhead to transport the oil and gas produced at the bottom of the well from the seabed to a processing platform 70km away, while also climbing up to 1300m (Figure 1); The second is to ensure the mixed transportation flow with a length of 261km from the processing platform to the onshore natural gas plant and the required capacity for transportation to the inlet of the onshore natural gas plant.

2) From the perspective of water depth: according to the current globally recognized view, the ability level classification of marine engineering and equipment is 10-100m, 100-300m is another difficulty level, 300-1500m can be called a world-class problem, and 1500-3000m is the pinnacle of the industry. The industry is accustomed to measuring the level and difficulty of technology based on water depth, as water depth determines which equipment is used for drilling. For the South China Sea continental slope area, the unique terrain and potential geological hazards may pose a significant threat to the submarine pipelines and underwater wellhead facilities for transporting natural gas, but our understanding of the risks of deepwater engineering has not yet formed a basic concept of magnitude. Therefore, from the perspective of experience and practical possibilities, the advantages of deep-water subsea hard pipelines over floating hoses are more obvious.

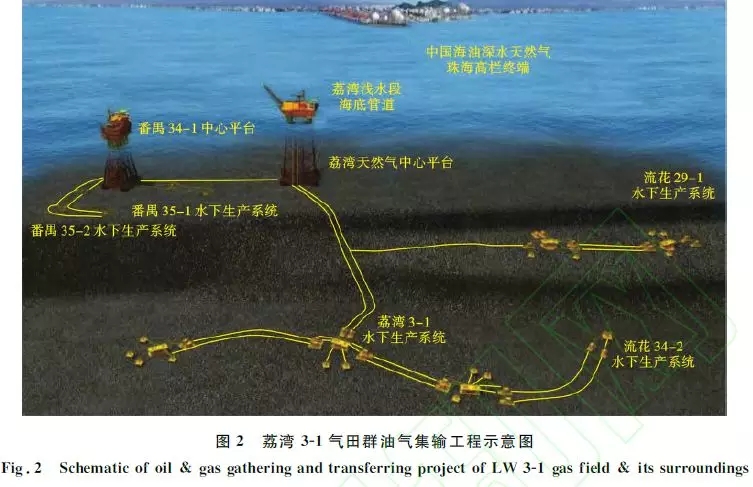

3) From the perspective of ensuring supply, Liwan 3-1 is a condensate gas field mainly composed of natural gas, along with surrounding gas fields such as Panyu 34/35 developed together (Figure 2). The main market is the Pearl River Delta Economic Zone, where natural gas enters the Guangdong pipeline network after landing, accounting for more than 50% of the total supply of the pipeline network; But there may be 3-4 typhoons passing through and affecting the entire production area every year, ensuring stable natural gas supply is the biggest challenge. Therefore, the selection of critical center processing platforms (floating or fixed platforms) and the evaluation of the safety and reliability of the selected platforms in the gathering and transportation system have become the core issues in ensuring supply.

4) From the perspective of offshore engineering oil and gas gathering and transportation, the Liwan 3-1 gas field is located in the middle and lower edge of the deep-water continental slope in the northern South China Sea, in a gentle slope area on the continental slope of the South China Sea. The straight-line distance from the gas field to the edge of the continental slope is 69km, and there are more than 10 gullies of varying depths distributed on this section of the slope. Under the premise of ensuring mixed transportation liquidity, it is the best choice to use hard pipes to lay along the gullies. However, the pipeline connection will change from the original planned straight line connection to a 3-segment folded line connection, and the mixed transportation distance will increase by more than 10km. The flow guarantee may be close to the transportation limit at that time.

In addition, the gas field forms two subsea well clusters in the deep-water seabed area, where the oil and gas from five wells converge and then converge towards the center point from the two subsea well clusters before starting to climb. 1500m deep seabed means 150 atmospheres of pressure, a low temperature close to 0 ℃, and the formation of a large elevation difference of oil, gas, and water multiphase transport from 1500m underwater to 200m underwater at the edge of the continental slope. This is the main basis for the "deep shallow land" development model proposed in this article, especially the dual pipeline transportation model proposed in the conceptual design, which is a fixed treatment platform from the seabed to the slope of the land. It creates possibilities for low production single pipeline operation in the early and later stages of production and gas fields, circulation path carrying liquid when a large amount of liquid accumulates in a single pipeline, and emergency backup to ensure the safety guarantee mode of minimum transportation volume.

5) From the perspective of building a "central gathering and processing plant" project, a super large offshore oil and gas gathering and processing facility with an annual natural gas processing capacity of 120 × 108m3 needs to be built offshore beyond 260km from the mainland, while providing an outlet pipeline pressure of 24MPa, making it an epoch-making giant project in the history of marine engineering. It is preliminarily estimated that the total weight of the platform is about 70000 tons, and research has found that the economic and stable production advantages of this plan are greater than those of floating platforms. If a processing plant with the same processing capacity is built on land, combined with remote control of the entire underwater production section and dehydration, water treatment, ethylene glycol regeneration, and ethylene glycol storage, even without considering oil storage and light hydrocarbon separation, it must occupy at least 15 × 104m2 or more.

6) From the perspective of engineering development difficulty: Regarding the Liwan 3-1 project, many experts and scholars are asking a question, that is, at the same time, China National Offshore Oil Corporation (CNOOC) is constructing deep-water series equipment such as the "Offshore Oil 981" that can adapt to the world and target the South China Sea, with an operating depth of up to 3000m. So, what is the technical difficulty of developing the Liwan 3-1 project? Taking typhoons as an example, "Offshore Oil 981" is a mobile drilling platform. When encountering the worst weather conditions (such as super typhoons), it can handle underground safety within the effective time of typhoon forecasts, and carry out planned overall platform evacuation without the need to resist excessively harsh weather. However, in order to ensure the normal supply of natural gas in the Pearl River Delta region during a super typhoon, the Liwan 3-1 gathering and transportation platform must maintain stable production. Therefore, the platform with a designed lifespan of 20 years must withstand the impact of dozens of severe typhoons, and the challenge of ensuring the safety of the platform's natural gas input and output systems and the flow safety of the entire gathering and transportation system is extraordinary.

Main technological innovations in oil and gas gathering and transportation projects in the deep-water continental slope area of the South China Sea

2.1 revealed the thermodynamic coupling mechanism of hydrate generation in multiphase mixed transportation systems of deep-water oil and gas fields, proposed a safety guarantee technology for 1500m deep-water high altitude difference dual circuit multiphase gathering and transportation, and created a "deep shallow land" gathering and transportation engineering model for oil and gas fields in the deep-water continental slope area of the South China Sea

1) The thermodynamic and dynamic coupling mechanisms of hydrate generation, growth, and aggregation in natural gas condensate mixed transportation systems under deep-water, high-pressure, and low-temperature environments have been revealed. The bidirectional growth prediction model of hydrate shells has been improved, and the conditions for hydrate formation in deep-water natural gas condensate mixed transportation systems have been determined.

2) Analyzed the thermodynamic mechanism of natural gas condensate mixed transportation system based on boundary molar mass characterization, established a multiphase steady-state flow model of oil, gas, and water that covers the effects of coke soup effect and potential energy, proposed a transient model for coupled interphase mass transfer, and developed a multi-level natural gas condensate mixed transportation flow prediction method; A flow analysis system based on multiphase flow pattern judgment, phase state and hydraulic thermal coupling field analysis has been constructed. Established an integrated multiphase mixed transportation system coupling analysis model for the wellbore underwater facilities pipeline network of Liwan 3-1 gas field group, and a corrosion prediction method for multiphase condensate water in low-temperature areas; Developed a collection and transportation pressure system, cleaning strategy, and hydrate dynamic control process for a deep-water reconnection system; We have developed a multiphase corrosion prevention and control technology that combines deep water high-temperature bimetallic composite pipes with low-temperature carbon steel. A safety guarantee technology method for deep-water long-distance, dual circuit oil, gas, and water multiphase gathering and transportation has been proposed.

3) A "deep shallow land" oil and gas gathering and transportation model has been created to address the complex environmental conditions of the northern slope of the South China Sea in China, consisting of a deep-water underwater production system, long-distance and high altitude multiphase mixed transportation pipelines, ultra large platforms, and land terminals; We have built a natural gas gathering and processing center platform with a quality of over 70000 tons, creating a transfer base for the "deep shallow land" development model; The largest environmentally friendly terminal in Asia with a design capacity of up to 200 × 108m3/a has been built, providing an onshore receiving and processing base for deepwater oil and gas. Relying on the Liwan 3-1 deepwater gas field project, the "deep shallow land" gathering and transportation engineering model for oil and gas fields in the deepwater continental slope area has been implemented (Figure 1), which has significant safety and economic advantages compared to using the deepwater floating engineering model, and ensures stable gas supply.

2.2 Breakthrough in key technologies for the design, construction, and installation of ultra large offshore oil and gas gathering and transportation processing systems, and improvement of the safety assurance technology system for ultra large offshore natural gas gathering and transportation platforms

1) We have developed a jacket platform design technology for the coupling of wind, waves, currents, and unique internal waves and currents in the South China Sea. We have proposed an intelligent analysis method for the sliding launch of ultra large jackets, thereby achieving real-time tracking and analysis of the entire process of jacket launch posture. We have developed a technology for storing ethylene glycol in the legs of a jacket, achieving a storage capacity of 2000t for four legs, greatly reducing the weight of the upper module and providing strong support for hydrate prevention and control in deepwater gathering and transportation systems.

2) Developed ultra long steel pile design and installation technology under complex engineering geological conditions, with a single pile diameter of 2743mm, length of 158m, mass of 750t, and mud depth of 135m, creating a world record for steel pile diameter, length, and quality. We have conquered the pile tip design technology under the interaction of seabed rock and soil strata, as well as the dynamic monitoring technology for pile driving in 200m deep water.

3) We have developed high-precision multi-point synchronous control load transfer and positioning technology for ultra large deepwater natural gas gathering and transportation platforms, as well as 3D simulation technology for joint operation and hoisting of multiple different models of cranes during the construction process of ultra large pipeline racks. We have also achieved significant breakthroughs in the construction technology of large platforms.

4) We have developed a four in one cyclic verification technology for the design, model testing, virtual simulation, and installation measurement of ultra large structures. By analyzing real-time monitoring data throughout the installation process of offshore structures, we have verified and improved the design technology and testing methods.

5) We have developed a routing evaluation method based on three-dimensional simulation of the seabed, and developed stability analysis and protection technologies for high-pressure, large-diameter (762mm), small diameter to thickness ratio (20.7-23.9), and long-distance (261km) submarine oil and gas mixed transportation pipelines.

6) We have developed a multi-source and multi factor coupled safety analysis technology for offshore platforms, as well as a torch zoning emission technology. This has solved the quantitative evaluation problem of the impact of platform smoke exhaust on helicopter takeoff and landing, as well as the problem of the impact of large natural gas platform torch emissions on platform safety. We have also improved the safety guarantee technology system for ultra large offshore natural gas gathering and transportation platforms.

2.3 has broken through the core technologies of high-resolution deep drag engineering geophysical exploration and deep water engineering geological survey analysis, independently established deep water engineering survey equipment and technical system, and identified and evaluated engineering geological hazards in the northern slope area of the South China Sea

1) A high-resolution deep towing survey, processing, and interpretation technology with dual ship positioning deep towing operations and distortion correction technology for rugged seabed strata as the core has been formed, achieving an international advanced level of 1500m depth multi beam depth measurement accuracy better than 0.5% of water depth and a shallow layer profile longitudinal resolution better than 0.3m, thus forming a complete deep water engineering survey technology system.

2) We have developed an internationally advanced in-situ testing and sampling system for seabed at a depth of 2000m. The static penetration test depth reaches 40m below the seabed, the in-situ vane shear test and T-Bar Testing depth reaches 20m, and the constant rate fixed piston sampling length reaches 12m. The independently developed 3000m deep engineering geological drilling coring tool based on drilling fluid pressure drive can achieve continuous coring without drilling, creating a domestic record of 87.3% sampling yield for 1720m deep drilling and 100m deep drilling. Established a deepwater engineering geological analysis technology based on in-situ testing, borehole sampling, and geotechnical analysis

Art has broken foreign monopolies.

3) We have established a technical system for identifying and evaluating deep-water geological hazards, and developed a geological hazard risk assisted decision-making system. Analyzed the causes of geological hazards in the northern slope area of the South China Sea, and developed corresponding geological hazard identification techniques and geological risk assessment methods; We have established a landslide instability prediction model for the northern slope of the South China Sea and conducted a quantitative evaluation of geological hazards in submarine pipelines based on deep-sea canyon areas; Developed a geological hazard risk assessment and decision-making assistance system; A deep-water engineering geological environment database covering 17500km2 of the northern slope area of the South China Sea has been established, achieving multidisciplinary data standardization management of the deep-water seabed environment in the South China Sea and accurate and efficient assessment of geological disaster risks.

2.4 Developed key materials and equipment such as high-pressure and small diameter to thickness ratio sea pipes, bimetallic composite corrosion-resistant sea pipes, underwater manifolds, and pipe end fittings, and initially established a localization system for underwater core equipment

1) We have achieved the localization of high-pressure, large diameter, small diameter to thickness ratio, and high-strength subsea pipelines. The Liwan 3-1 gas field uses two deep-water pipelines with a length of 79km and a diameter of 558.8mm, as well as one shallow water pipeline with a length of 261km and a diameter of 762mm. The total quality of the pipelines is 19 × 104t, all of which are domestically produced. We have overcome a series of challenges such as controlling low-temperature fracture toughness (steel pipe wall thickness above 30.8mm, requiring resistance to low temperature -10 ℃, impact fracture shear area ≥ 85% in drop hammer tear test), matching control of strength plastic toughness with high difficulty, diameter thickness ratio (20.7-23.9), and high performance stability requirements (allowable fluctuation range of yield strength is 100MPa). We have developed thick walled straight seam submerged arc welded pipes with high pressure, high steel grade, and small diameter to thickness ratio, achieving mass production of offshore pipes and filling the domestic gap.

2) The localization of deep-water seabed bimetallic composite pipes has been achieved. We have developed composite pipe ovality error control technology, pipe end automatic welding technology, pipe end precision turning and rounding new processes, which have improved the quality and dimensional accuracy of pipe end welding layers, as well as the efficiency of offshore pipe laying alignment and welding; We have developed testing techniques for the mechanical properties and corrosion resistance of composite pipe welded joints, and achieved large-scale production of high-quality composite pipes.

3) The localization of underwater pipeline terminals, online underwater manifolds, and underwater pump sleds has been achieved. Developed design, manufacturing, and installation technologies for subsea pipeline terminals, online underwater manifolds, and underwater pump sleds. We have overcome technical difficulties in underwater equipment manufacturing, welding and surface salt control, installation adaptability analysis, underwater precise positioning control, and hoisting, and formed a corresponding design, construction, and installation technology system. We have also established the first domestic underwater product manufacturing and testing base, successfully implemented the localization of 26 underwater products, and broken foreign monopolies.

2.5 has constructed an emergency system for production and operation of deepwater oil and gas fields, based on leakage and explosion modes. Preliminary research and development have been carried out on emergency maintenance technology and supporting equipment for 1500m deepwater subsea pipelines

1) Developed a deep water remote production monitoring, early warning, and management system. Based on the dynamic simulation of multiphase flow of oil, gas, and water in the deep water wet gas reconnection system, real-time identification of multiphase flow patterns of oil, gas, and water has been achieved for the first time. Dangerous working conditions such as hydrate blockage, corrosion, and sand production have been warned, and the injection and operation processes of chemicals have been optimized. The operation of the 1500m water long-distance gas field typhoon mode has been achieved, ensuring the safe and stable operation of the Liwan 3-1 gas field group.

2) We have established an emergency system for leaks and explosions in deepwater oil and gas fields. We have developed a three-dimensional leakage simulation analysis method for central gathering and transportation processing platform risers and submarine pipelines, proposed emergency plans and disposal plans for leaks and explosions, and have been applied in development projects in multiple deep water blocks in the South China Sea.

3) Developed emergency maintenance technology and supporting equipment for 1500m underwater facilities. Developed an emergency unblocking process and unblocking device that integrates active prevention and targeted unblocking; A sealing device and an underwater robot (ROV) intervention maintenance tool have been developed for different forms of damage to deep-water submarine pipelines, forming corresponding emergency response plans.

Implementation effect of 3 engineering schemes

Through the main technological integration and innovation of the South China Sea deep-water continental slope oil and gas gathering and transportation project, the Liwan 3-1 deep-water gas field was completed and put into operation in 2014, marking that China has the core technological ability to independently develop deep-water oil and gas fields and has reached the international advanced level. The completion and operation of the Liwan 3-1 gas field, as well as the successful rolling development of surrounding gas fields such as Liuhua 19-5, Panyu 34-1/35-2/35-1, and Liuhua 34-2 at depths of 280-1240m, mark the successful implementation of the integrated layout and rolling development strategy of "deep shallow land" and "gathering before transportation" in the deep-water continental slope area, laying a solid foundation for the economically effective and safe development of deep-water oil and gas resources on the northern slope of the South China Sea.

The Liwan 3-1 deep-water gas field and surrounding gas field oil and gas gathering and transportation project has broken through 5 major directions and 20 core technologies. The 1500m deep water oil and gas gathering and transportation engineering technology system created has been verified through practice and has overall reached the international advanced level, with 4 technologies being internationally leading. In 2014, the Liwan 3-1 gas field project was rated by Offshore as one of the world's top five deep-water marine engineering projects. As of the end of 2017, the farthest single well LH34-2-1 has a multiphase connection distance of 103km (ranking fifth in the world), and the demonstration project has stably transported 110.3 × 108m3 of gas to the Pearl River Delta region. After the project is put into operation, it has created direct economic benefits of 14.6 billion yuan, and the promotion and application of technological innovation achievements have created an output value of about 32.4 billion yuan.

4 Conclusion

Based on the National Science and Technology Major Project "South China Sea Deepwater Oil and Gas Development Demonstration Project", the South China Sea Deepwater Slope Area Oil and Gas Gathering and Transportation Project has established a 1500m deep water oil and gas gathering and transportation engineering technology system with independent intellectual property rights, and completed China's first deepwater oil and gas field - Liwan 3-1 demonstration project. The relevant technologies developed by this engineering project have been promoted and applied to the development of deepwater oil and gas fields in the South China Sea, such as Lingshui 17-2 and Liuhua 16-2, as well as cooperative block deepwater oil and gas field projects in West Africa, Brazil, and the Gulf of Mexico. The innovative development models and technologies formed provide a foundation for the development of oil and gas fields in the South China Sea region, which is of great significance to China's energy security strategy.

(The above article is reprinted in "China Offshore Oil and Gas" by Jin Xiaojian, Chen Rongqi, Zhu Xiaohuan of Offshore Oil Engineering Co., Ltd. | Compiled and published by Offshore Oil and Gas Network)

High-end pipe manufacturing equipment

manufacturing experience

professional team

Plant a total area of 10,000

square meters

9 inventions, 11 utility models <bR />2 appearance designs

2016-2019 © Huajin Heavy Equipment All Rights Reserved Xiang ICP Preparation 12002607 Number