TIME: 2018-07-15

On July 6th, Li Wenjie, Deputy Manager of the China Russia East Pipeline Project Department of China Petroleum Pipeline Company, stated in an interview with reporters in Heihe City, Heilongjiang Province that as of now, 51% of the northern section of the natural gas pipeline (Heihe Heilongjiang Changling Jilin) has been completed, and the shield tunneling projects for the two throat tunnels crossing the bottom of the Heilongjiang River and the Nemur River are progressing smoothly. It is understood that the project not only has a final output of up to 38 billion cubic meters per year, which is the highest value to date, but also will build a model for China's first intelligent pipeline.

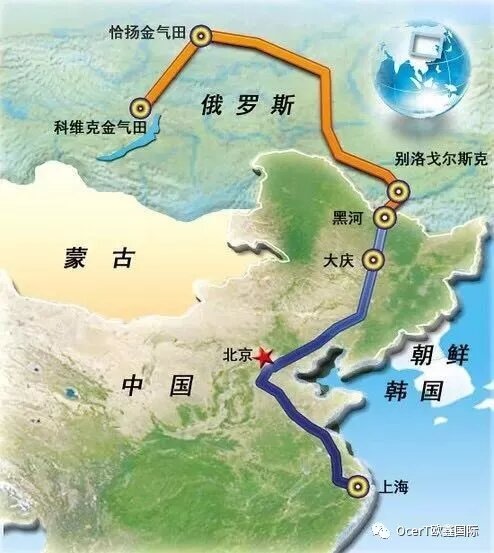

The construction of the China Russia pipeline project began in June 2015 and will be carried out in stages for the northern section (Heihe Changling), middle section (Changling Yongqing), and southern section (Yongqing Shanghai). It is expected that the northern section will be put into operation in October 2019 and the entire line will be connected by the end of 2020. The China Russia East Line Natural Gas Project is another important achievement of strengthening the comprehensive energy cooperation partnership and deepening the comprehensive strategic cooperation partnership between China and Russia. It is also a major project for China Petroleum to serve the "the Belt and Road" initiative and build four major energy transport channels in China. In May 2014, China and Russia signed a natural gas purchase and sales contract for the China Russia East Line, with a total value of over 400 billion US dollars, an annual gas supply of 38 billion cubic meters, and a term of up to 30 years.

The starting point of the China Russia East Gas Pipeline Project is located on the China Russia border in Heihe City, Heilongjiang Province. It passes through 9 provinces and cities including Heilongjiang, Jilin, Inner Mongolia, Liaoning, Hebei, Tianjin, Shandong, Jiangsu, and Shanghai, and ends in Shanghai. The total length is 3371 kilometers, making it the largest and highest pressure long-distance natural gas transmission pipeline in China. This project will have a positive impact on driving the development of basic industries such as steel smelting, pipe making, and equipment manufacturing in China, and will also effectively promote the coordinated development of upstream, midstream, and downstream industrial chains such as domestic gas fields, pipelines, gas storage facilities, and natural gas utilization projects. In the process of implementing the project, PetroChina adheres to the development concept of "innovation, coordination, green, openness, and sharing", and strives to build it into a demonstration project that promotes economic development, serves environmental improvement, and benefits the people.

The China Russia East Gas Pipeline Project is an innovative business card for China's oil pipeline construction.

This project is China's first cross-border long-distance natural gas pipeline project with the world's largest single pipeline transmission capacity, using 1422mm ultra large diameter, X80 high steel grade pipes, and a high pressure rating of 12 megapascals. The natural environment along the pipeline is complex, with permafrost, water network swamps, and forest belts alternately distributed. The lowest temperature in winter can reach minus 40 degrees Celsius, posing a huge challenge for pipeline construction. In order to build the China Russia East Gas Pipeline well, China Petroleum Organization has carried out a series of technical research topics, including the manufacturing of 1422mm X80 natural gas pipeline pipes, pipeline fracture control, pipeline engineering design and construction, and equipment. Thirteen technical standards have been formed, including the manufacturing of 1422mm X80 pipes, pipeline engineering design and construction, and technical conditions for valve fittings. At the same time, the full-scale explosion test of X80 and 1422mm natural gas test media pipelines was carried out for the first time internationally, verifying the safety and reliability of independently developed steel pipes.

Inside the tunnel, the China Russia border crossing point (from the Chinese side to the Russian side)

During the construction period of the northern section of the experimental section, all participating personnel aimed to achieve a large-scale production line for the entire process. A total of 12 automatic welding machine groups, 1492 participating personnel, and 1164 machinery and equipment were invested, achieving a fully automatic welding rate of over 90%. The engineering route adopted a low-temperature -30 ℃ fully automatic welding process, and the station adopted a low-temperature -45 ℃ welding process, as well as AUT, PAUT+TOFD, DR, and high-power X-ray non-destructive testing technologies, achieving 48 technical experimental results.

As the first third-generation oil and gas pipeline in China, this project is also a pilot project of PetroChina's "smart pipeline" construction. With the goal of "full digital handover, full life cycle management, and full intelligent operation", by virtue of the construction of "mobile terminal+cloud computing+big data" and "smart site" of Internet plus+units, this project integrates data information, builds an intelligent integrated application platform for information systems throughout the life cycle shared by supervisors, contractors, and owners, realizes information collaboration and process collaboration, promotes the transformation of pipeline data from scattered distribution to unified sharing, the transformation of risk control mode from passive to active, and the transformation of pipeline information systems from isolated and decentralized to integrated and interconnected, so as to build an intrinsically safe and efficient intelligent pipeline.

The China Russia East Gas Pipeline Project is also a "green business card" for China's oil pipeline construction.

China Petroleum strictly implements national environmental protection laws and regulations, adheres to the "three simultaneous" system requirements of "simultaneous design, simultaneous construction, and simultaneous use" of environmental protection facilities and main projects, and strengthens environmental protection control measures during engineering design and construction processes. During the design phase, optimize routing and select routes reasonably, avoid various ecological and water source protection areas as much as possible along the pipeline, pass through forest areas with a straight route, reduce deforestation, and minimize the occupation of fertile land as much as possible; Establish an environmental management organization during the implementation phase, establish a health, safety, and environmental management system, and supervise and manage the formulation and implementation of environmental protection measures along the project route.

During the construction period, actively obey and cooperate with government inspections and guidance, strengthen the protection of animals and plants, and control environmental sensitive targets such as water sources, rivers, and nature reserves, to ensure the construction of safe, environmentally friendly, and green projects.

The introduction of natural gas from the China Russia East Line will have a positive and far-reaching impact on enhancing China's clean energy supply, optimizing energy structure, achieving energy conservation and emission reduction, improving atmospheric environment, controlling air haze, improving people's quality of life, and achieving sustainable socio-economic development. The China Russia East Gas Pipeline imports 38 billion cubic meters of clean and high-quality natural gas annually.

Compared with coal, it can reduce carbon dioxide emissions by 163.78 million tons, sulfur dioxide emissions by 1.82 million tons, nitrogen oxide emissions by 460000 tons, and dust emissions by 840000 tons. This will effectively alleviate the natural gas shortage in Northeast China, improve the air quality in the Beijing Tianjin Hebei region, and promote energy structure adjustment in the Yangtze River Delta region.

(The above article is reprinted on OceanT Ouxin International)

High-end pipe manufacturing equipment

manufacturing experience

professional team

Plant a total area of 10,000

square meters

9 inventions, 11 utility models <bR />2 appearance designs

2016-2019 © Huajin Heavy Equipment All Rights Reserved Xiang ICP Preparation 12002607 Number