Recently, many people have consulted the editor about the working principle of the expanding machine? This issue is believed to be troubling many people. Next, the editor will introduce the working principle of the expanding machine to you. Let's learn more with the editor.

First, let me briefly introduce the diagram of the expanding machine: the expanding machine belongs to the straight seam metal welded pipe shaping equipment. It uses a conical expanding head to expand inside the steel pipe, eliminating the forming pressure and welding stress of the steel pipe, and ensuring that the true diameter of the entire length of the straight seam welded steel pipe is consistent. The equipment consists of a small car, an expander, a working sleeve, a fixed seat, an oil cylinder, a lubrication station, a bench, a hydraulic station, and an electrical control system. The expander is installed on the car, connected to the oil cylinder by a working sleeve. The expander is composed of an expander head, expansion block, guide plate, pull rod, etc. A large-scale equipment that ensures the external diameter of straight seam metal welded pipes and eliminates stress through segmented mechanical extrusion and expansion technology.

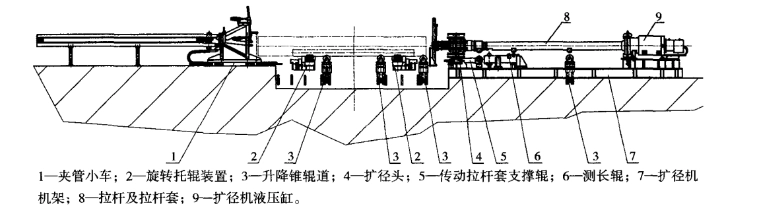

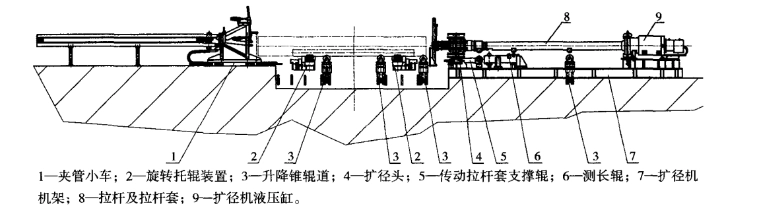

Equipment composition

The mechanical expanding machine is composed of a rotating roller device, a lifting cone roller track, a transmission rod sleeve support roller, a length measuring roller, a pipe clamping car, an expanding head, a rod, a rod sleeve, an expanding machine hydraulic cylinder, and a frame. The function of a mechanical expanding machine is to use the expanding head to gradually expand the large-diameter straight seam submerged arc welded pipe, in order to obtain the roundness, straightness, and dimensional accuracy required by standard technical requirements.

Process

The washed pipe is sent to the rotating roller device on the centerline of the expanding machine. Using this rotating roller device, combined with a camera system, the pipe weld seam is precisely rotated to the 12 o'clock position to ensure that the weld seam can enter the groove of the upper sector block of the expanding tool during the subsequent expansion process. Lifting cone roller conveyor tube

The sub rises to the centerline of the expanding machine, and the position is controlled by the displacement sensor in the lifting hydraulic cylinder. The clamp car moves forward and is controlled by a metal detector to detect the tail end of the pipe and clamp it firmly. At the same time, a signal is sent to start the feeding roller of the clamp car. The position is controlled by an encoder. During the movement, the metal detector set at the expanding head end detects the pipe

Measure the position of the pipe at the front end. The length of the pipe is combined with the expansion head to automatically calculate the optimal number of expansion steps. The jaws of the pipe clamp can rotate to avoid damaging the pipe wall. During the forward process, the height of the pipe clamp can be adjusted to compensate for the straightness deviation of the pipe and optimize the straightening effect of the expanding machine.

According to the calculated step size, the pipe clamp car sends the pipe into the expanding head in the first step. Before the first step of expanding, the supporting roller of the transmission rod sleeve supports the expanding head. Until the first step of expanding the diameter is connected to the cantilever rod sleeve of the main hydraulic cylinder and the expanding head connected to it with a flange, the supporting roller of the transmission rod sleeve is lowered by one wall thickness. first

After the step expansion is completed, the head end of the pipe is expanded to the required size. The necessary travel of the expanding tool is achieved by driving the rod through the hydraulic cylinder of the expanding machine. According to the relationship between the expanding tool and the pipe diameter, use a position detector to control and complete this stroke.

The pipe advances further and the next expansion stroke begins. This step is repeated until the feeding of the pipe can no longer be carried out through the clamping car. The clamp releases the pipe, and the final feed is driven by the support roller of the transmission rod sleeve, which measures the length by the measuring roller. After the expansion of the pipe is completed, the transmission rod sleeve is supported

The supporting roller then sends the pipe back to the clamp. The pipe clamp clamps the pipe and pulls it back to its starting position. The clamp opens and the clamp car returns to its initial position. The expanded pipe is sent out, and the expansion of one pipe is completed.